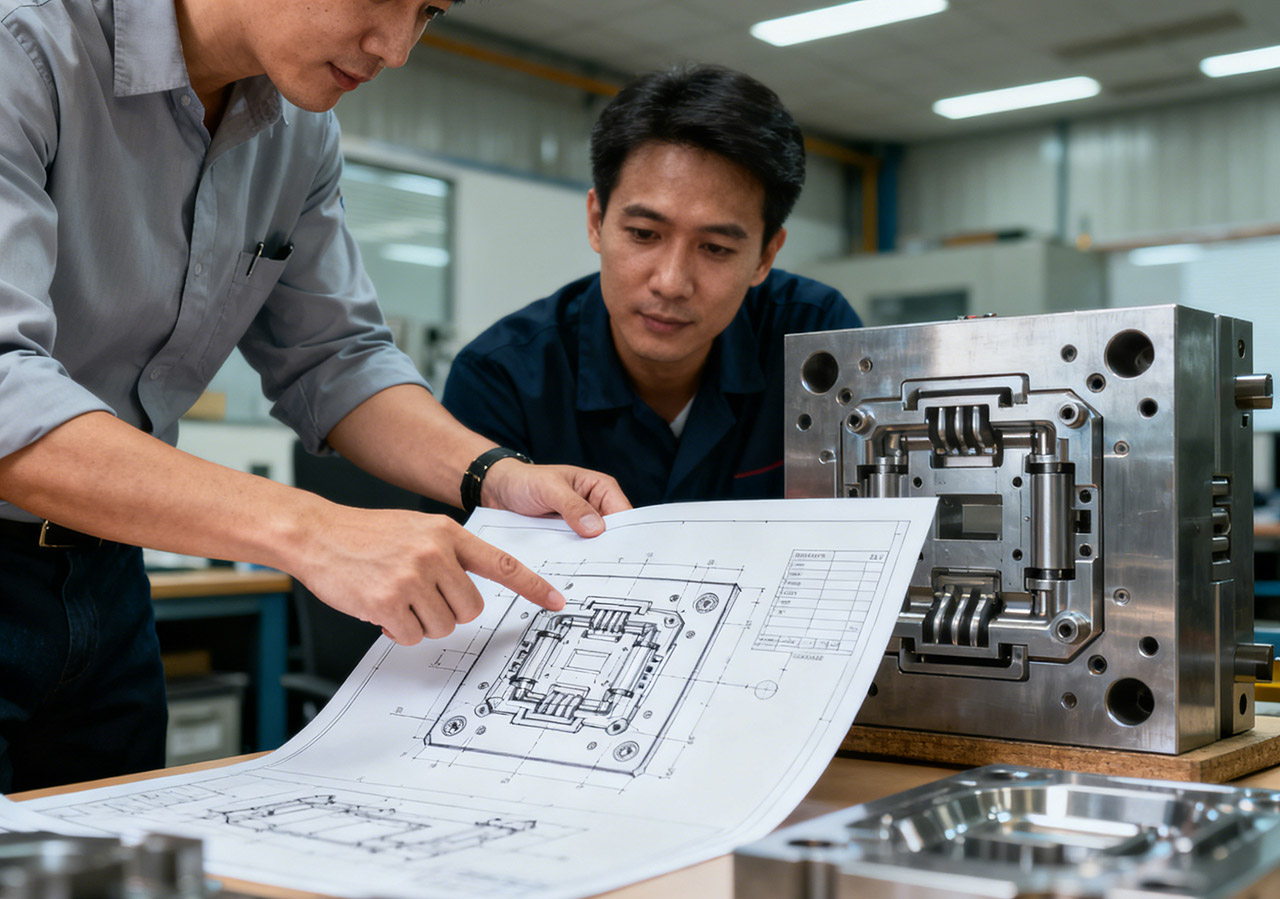

In plastic product design and manufacturing, injection molding is one of the most common and fundamental processes. Standard injection molding can achieve shaping, gloss, and basic textures, but as demands for higher quality, aesthetics, and functionality continue to grow, traditional methods alone are no longer sufficient. This is where a variety of advanced injection molding techniques come into play, helping achieve the perfect balance between appearance, touch, structure, performance, and cost.

As an experienced Injection Molds Manufacturer and Plastic Parts Manufacturer, Ideal Mold has been deeply engaged in mold making and plastic part production for many years. We provide solutions ranging from small precision products to medium-sized components, serving industries such as automotive parts, household appliances, industrial automation, and medical devices. Based on our experience in toolmaking and molding processes, this article will analyze seven advanced injection molding techniques, combining practical applications with CMF (Color, Material, Finish) design insights.

1. Multi-Color / Multi-Shot Injection Molding

Definition & Features

Uses two or more colors/materials in the same molding cycle.

Enables plastic + plastic or plastic + elastomer combinations for distinct visual and tactile effects.

Advantages

Creates strong visual contrast and brand recognition.

Reduces secondary painting or coating processes.

Expands design freedom by integrating multiple colors or textures into a single part.

Challenges

Complex mold design and runner/gate control.

Requires compatibility between different materials (shrinkage, bonding strength, thermal expansion).

Applications: Smart wearable casings, game controller buttons, colorful plastic housings.

2. Overmolding / Insert Coating

Definition & Features

A base part is molded first, followed by a second injection layer (e.g., TPE, silicone) for soft grip or protection.

Advantages

Improves user comfort with a soft touch.

Provides anti-slip and shock absorption.

Enhances durability and product value.

Challenges

Adhesion issues between base and overlay.

Longer cycle times and higher costs.

Applications: Tool handles, mobile device frames, watch cases.

3. Insert Molding

Definition & Features

Places metal inserts or other components into the mold before injection, resulting in integrated structures.

Advantages

Combines mechanical strength with electrical/functional properties.

Reduces assembly steps and increases reliability.

Achieves precise fits in a single molding process.

Challenges

Demands high accuracy in mold design and insert positioning.

Potential stress or bonding challenges between different materials.

Applications: Metal studs, electronic contacts, reinforced connectors.

4. Nano Molding Technology (NMT)

Definition & Features

Metal surfaces are pre-treated (etching, blasting, oxidation) before plastic is injected, achieving seamless bonding.

Advantages

Delivers a premium metallic look with reduced weight and cost.

Enhances product integration while maintaining structural reliability.

Strong overall appearance without visible seams.

Challenges

Requires advanced surface treatment for bonding strength.

Thermal expansion mismatch between metal and plastic may cause internal stress.

Applications: Smartphone frames, laptop housings, decorative high-end electronics.

5. Micro-Foam / Foam Injection Molding

Definition & Features

Introduces physical or chemical foaming agents during injection, forming microcellular structures.

Advantages

Reduces weight and material consumption.

Improves insulation, damping, and sound absorption.

Creates lightweight yet dimensionally stable products.

Challenges

Difficult to control uniform bubble distribution.

Requires precise processing parameters and specialized machines.

Applications: Shoe soles, handles, housings, cushioning components.

6. Paint-Free Injection Molding (In-Mold Decoration / In-Mold Color)

Definition & Features

Uses pre-colored or effect-enhanced resins to achieve metallic, ceramic, or textured effects directly in molding.

Advantages

Eliminates painting and reduces VOC emissions.

Delivers consistent quality without spray-related defects.

Improves efficiency and shortens lead time.

Challenges

Higher raw material cost and strict molding conditions.

Sensitive to color uniformity and flow marks.

Applications: Home appliance panels, automotive interiors, cosmetic cases.

7. Injection-Compression Molding

Definition & Features

Combines injection with compression molding to achieve high precision and thin-wall parts.

Advantages

Enables ultra-thin designs with less material.

Achieves superior surface quality and flatness.

Suitable for premium appearance requirements.

Challenges

Demands precise temperature and pressure control.

Requires advanced tooling and higher equipment investment.

Applications: Smartphone glass-like back covers, decorative thin panels.

Comparative Insights for CMF Design

When selecting advanced injection molding technologies, designers and manufacturers should consider:

Appearance & Touch: Do you need metallic gloss, soft grip, texture, transparency?

Functional Needs: Anti-slip, waterproof, wear resistance, EMI shielding?

Cost Factors: Material + tooling + cycle time + yield rates.

Lead Time: Mold building, trial runs, secondary processing.

Sustainability: Paint-free, reduced VOC, recyclable resins.

Precision & Tolerance: Is it a high-precision or visible component with strict cosmetic requirements?

Ideal Mold: Your Reliable Partner

As a professional Injection Molds Manufacturer and trusted Plastic Parts Manufacturer, Ideal Mold has extensive experience not only in conventional injection molding but also in advanced technologies such as multi-shot molding, overmolding, insert molding, paint-free molding, and more.

Our strengths include:

Precision Mold Development: Meeting high-tolerance requirements for complex small components.

Diverse Industry Solutions: Automotive, home appliances, industrial automation, medical devices.

One-Stop Service: From mold design, injection molding, assembly to surface treatment.

Strict Quality Control: Ensuring every plastic part meets international standards.

With our expertise as a leading Injection Molds and Plastic Parts Manufacturer, we help clients balance design innovation, manufacturability, and cost efficiency.

Future Trends

Integration & Modular Design: Combining multiple functions and aesthetics into one part.

Green Manufacturing: Adoption of recyclable resins, bio-based plastics, and paint-free processes.

Precision Micro-Structures: Nano-level surface treatments for premium electronic devices.

Digital Manufacturing: Simulation-driven process optimization to reduce trial and error.

Conclusion

Injection molding is a fundamental process, yet its branches and variations are vast. From enhancing aesthetics (multi-color, overmolding, paint-free) to integrating structures (insert molding, nano molding) and achieving lightweight precision (micro-foam, injection-compression), each advanced technology creates new value.

Ideal Mold, as a professional Injection Molds Manufacturer and reliable Plastic Parts Manufacturer, is committed to delivering innovative, high-quality, and cost-effective solutions for global clients. We help transform product concepts into reality—ensuring every component combines functionality, beauty, and manufacturability.