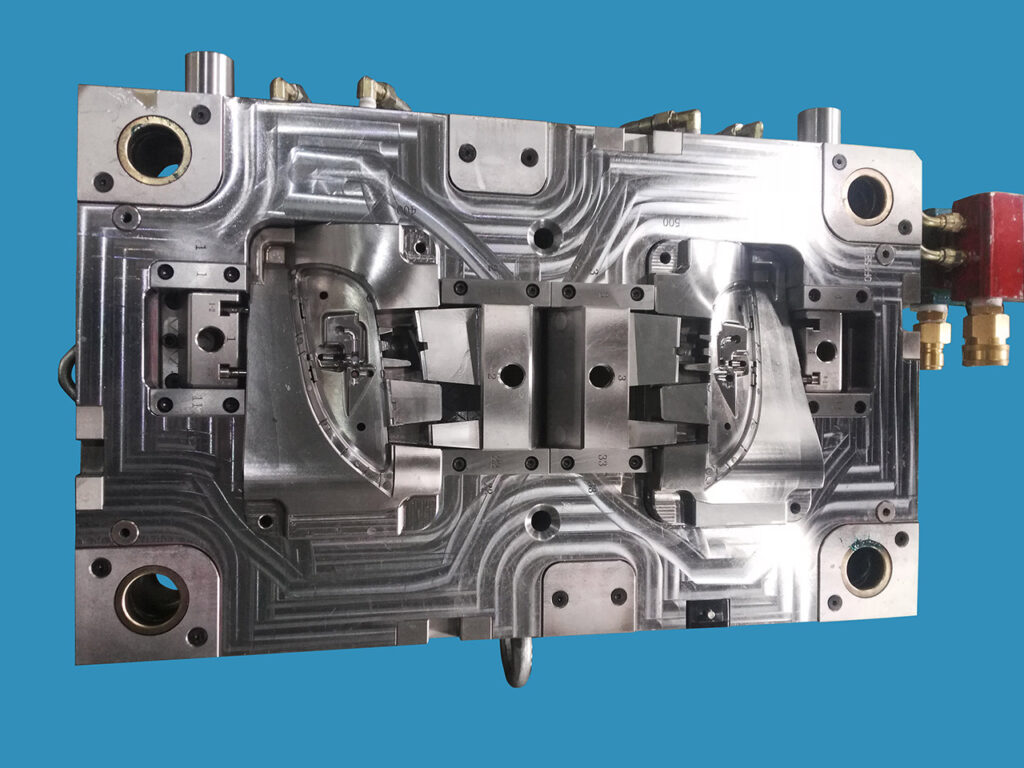

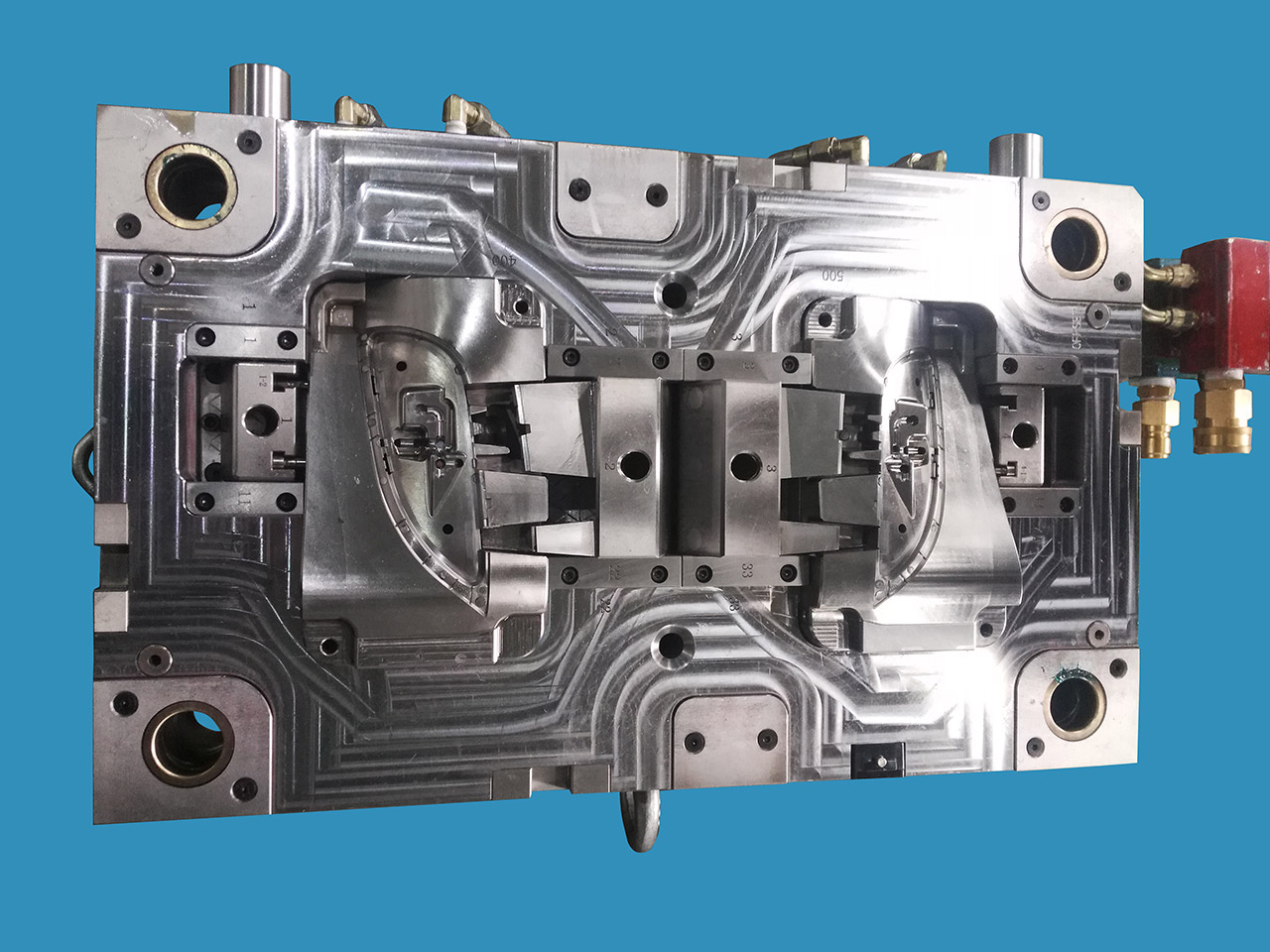

As the race for electric vehicle (EV) range reaches the “every watt counts” stage and smart cockpit designs demand ever higher component integration, automotive injection molding has long evolved from a “basic processing step” to a key pillar of the automotive industry’s competitiveness. With 12 years of dedicated experience in automotive injection molding, idealmold has witnessed molding technology resonate with automotive innovation. Drawing on thousands of successful projects, we have developed precise molding capabilities tailored to diverse vehicles and scenarios.

20 Years of Expertise: We Understand Cars—and the “Automotive-Grade” Standards of Injection Molding

Automotive injection molding differs fundamentally from general plastic molding due to the extreme operating conditions and rigorous standards. Engine components must withstand temperature cycles from -40°C to 150°C, chassis parts endure long-term vibration and impact, while interior components must meet VOC regulations and tactile requirements. Such challenges make automotive injection molding far more than “material filling”; it is a full-chain systems engineering process.

Since entering the automotive injection molding field in 2005, idealmold’s services have expanded from traditional fuel vehicle interior components to core areas of EVs, including battery enclosures, radar housings, and smart cockpit modules. Over two decades, we have partnered with numerous domestic and international automotive brands, completing projects across customized solutions—from dashboards in fuel vehicles to high-voltage harness holders in EVs. Every component’s molding parameters are derived from our deep understanding of real automotive operating conditions.

We have also established dedicated “Material-Process-Inspection” databases for different automotive systems. For instance, engine-adjacent components often use modified PA66 with glass fiber and high-temperature mold control; interior components use low-VOC TPO materials with vacuum degassing to minimize odors.

Technical Mastery: Our Three Core Competencies in Automotive Injection Molding

In automotive injection molding, precision, stability, and adaptability are the top concerns for clients. Through continuous technological upgrades and equipment iteration, idealmold has turned these challenges into our core strengths, meeting demands from traditional fuel vehicles to smart EVs.

- Full-Process Stability for Large-Scale Production

Automotive parts often require mass production in units of tens of thousands. Stability directly affects production line efficiency. We have implemented an SOP-controlled system covering every stage—from raw material to finished part. - Customized Adaptability for Innovative Automotive Needs

Whether addressing lightweighting requirements in EVs or complex-shaped components in smart cockpits, we provide rapid, tailored solutions:- Lightweighting: Using modified PP with micro-foaming technology, part weight is reduced by 15–20% without compromising strength, applied in EV battery cover components.

- High-Temperature Resistance: Using PEEK specialty materials and high-temperature molding, engine sensor housings can withstand over 200°C, meeting traditional fuel vehicle conditions.

- Integration: Utilizing two-shot injection molding, components of different materials are produced in a single process—e.g., smart cockpit button panels with hard shell + soft-touch integration, enhancing product quality and assembly efficiency.

Authoritative Certifications & Client Endorsements: Visible Automotive-Grade Quality

In automotive injection molding, trust is built on both authoritative certification and client recognition. idealmold consistently adheres to the highest industry standards, earning credibility through proven performance.

We are certified under IATF16949 Automotive Quality Management System and ISO9001 Quality Management System, which not only open doors to the automotive supply chain but also reaffirm our commitment to excellence.

Partnering with You: From Prototype to Mass Production, Driving Automotive Industry Advancement

As the automotive industry transitions toward electrification and intelligence, the innovation space for injection molding continues to grow. idealmold is not just a producer of automotive injection-molded parts but your full-cycle partner—from material selection advice in the design phase, to rapid prototyping (as fast as 24 hours), to stable mass production and after-sales support. We help reduce R&D costs and accelerate time-to-market.

If you are seeking custom automotive injection molding solutions or want to explore the technical details of molding for different automotive components, contact us today. Together, we can leverage precision molding to drive high-quality development across the automotive industry.