As the automotive industry accelerates toward electrification, intelligence, and sustainability, lightweight design has become a critical strategy for improving driving range, reducing energy consumption, and enhancing overall vehicle performance.

Among various manufacturing technologies, automotive plastic injection molding stands out for its advantages in lightweight construction, high precision, cost efficiency, and the ability to realize complex geometries—making it an essential process in modern automotive component manufacturing.

With over 20 years of experience dedicated to automotive injection molding, we focus on technological innovation and uncompromising quality standards, delivering customized plastic injection solutions to global automotive brands and component suppliers.

20 Years of Expertise in Automotive Injection Molding

For more than two decades, we have specialized exclusively in automotive plastic injection molding, evolving from producing basic interior components to manufacturing today’s high-precision, functional plastic parts.

Our products serve passenger vehicles, commercial vehicles, and new energy vehicles (EVs). We have successfully supplied injection-molded components to numerous well-known domestic and international automotive manufacturers, covering a wide range of applications, including:

- Interior components: dashboard frames, door panel clips, center console brackets

- Exterior components: bumper brackets, mirror housings, window guide rails

- Functional components: motor insulation parts, sensor housings, electrical protection components

Through long-term partnerships, we have gained deep insight into the automotive industry’s core requirements—high precision, production consistency, and stable multi-batch delivery. To meet diverse vehicle platform needs, we have established a fast-response, end-to-end system covering design optimization, mold development, and mass production, ensuring on-time delivery and a high customer repeat rate.

Core Technical Strengths in Automotive Plastic Injection Molding

We build our technical advantages across material selection, mold engineering, and process control, ensuring every component meets stringent automotive standards.

1. Automotive-Grade Material Selection Expertise

Different automotive applications require vastly different material properties.

- Interior parts demand low VOC emissions and environmental compliance

- Exterior parts require weather resistance, UV stability, and impact strength

- Functional parts must withstand high temperatures, provide insulation, and meet flame-retardant standards

We are highly experienced with automotive-grade engineering plastics such as PP, ABS, PC, and PA, enabling precise material selection based on functional requirements.

For example:

- For EV battery pack components, we use glass-fiber reinforced PA66, specially modified to deliver excellent heat resistance (above 120°C), impact strength, and electrical insulation—meeting strict safety requirements.

- For dashboard structural frames, we apply low-VOC PP materials, optimized through advanced molding processes to achieve odor levels ≤ Grade 3, in compliance with automotive interior environmental standards.

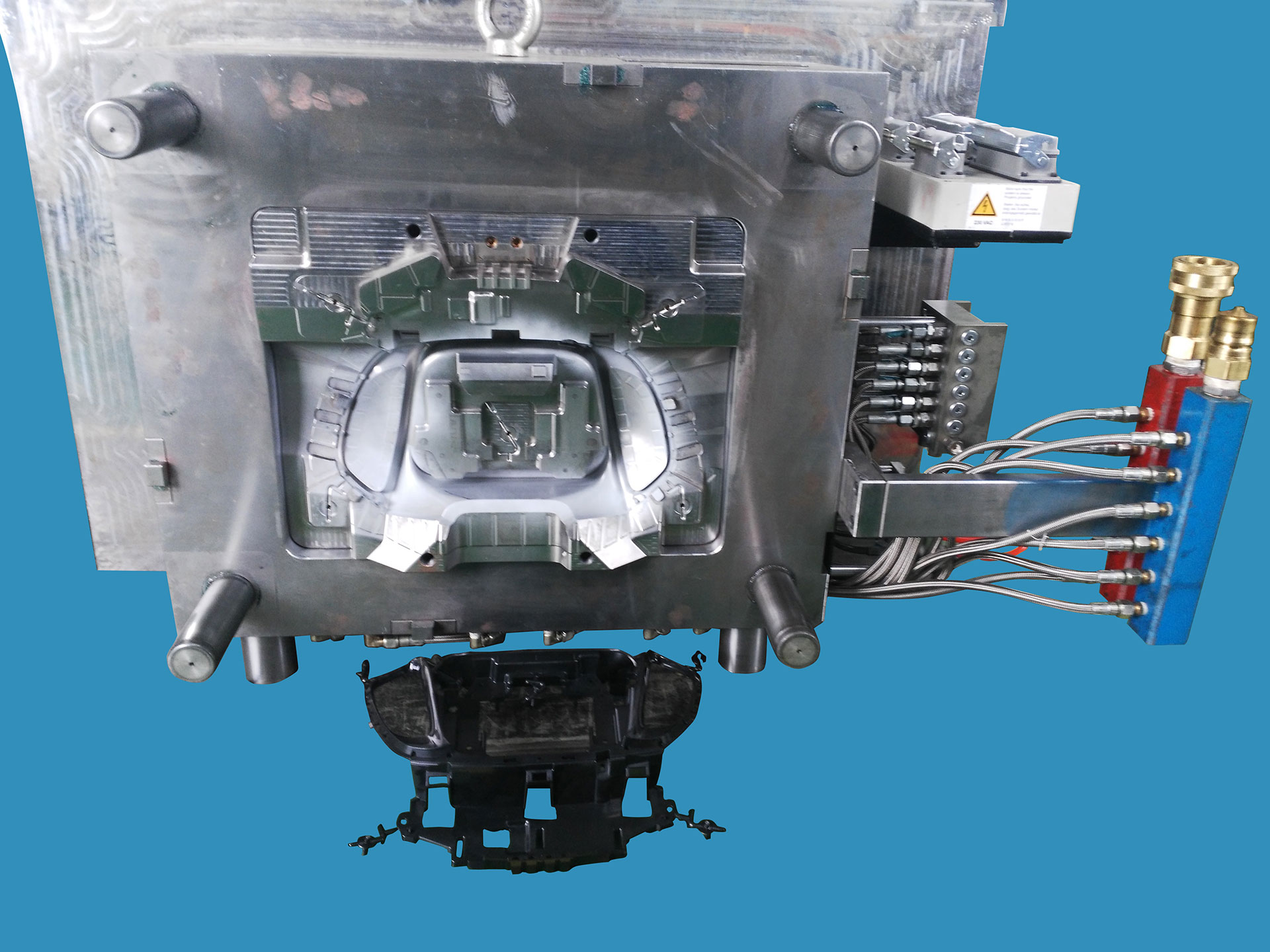

2. High-Precision Mold Design and Manufacturing

Molds are the foundation of injection molding quality and consistency. We operate an in-house mold development center staffed by experienced mold engineers. Using professional design software such as UG and AutoCAD, combined with mold flow analysis, we can predict and eliminate potential issues such as shrinkage, warpage, and weld lines before production begins.

Our mold manufacturing process utilizes high-precision CNC machining centers, EDM, and wire-cutting equipment, achieving tolerances of ±0.02 mm. For high-volume automotive projects, we design multi-cavity molds that reduce single-part cycle times to 15–30 seconds, significantly improving efficiency and cost control.

3. Strict End-to-End Process Control

Our intelligent injection molding workshop is equipped with 47 high-precision injection molding machines ranging from 60 to 1,000 tons of clamping force, supporting a wide variety of automotive components.

From raw material drying and injection molding to cooling, forming, and inspection, every step is monitored through digitalized, real-time data control. Key parameters such as injection pressure, temperature, and speed are continuously tracked to ensure batch-to-batch consistency.

For complex structures, we apply advanced technologies such as gas-assisted injection molding and insert molding, effectively resolving challenges related to uneven wall thickness, shrinkage, and deformation.

Certified to Meet Global Automotive Standards

Quality is non-negotiable in the automotive industry. We have established a comprehensive quality management system and obtained internationally recognized certifications, including:

- IATF 16949:2016 – Automotive Quality Management System

- ISO 9001:2015 – Quality Management System

In addition, our in-house laboratory is equipped with professional testing instruments for dimensional inspection, mechanical performance, and functional validation, ensuring that every production batch meets customer specifications and industry standards.

Partnering for the Future of Automotive Manufacturing

Automotive plastic injection molding continues to evolve alongside the industry’s transformation toward lightweight, intelligent, and electric mobility. We remain committed to advancing our capabilities through continuous innovation, leveraging 20 years of industry experience, strong technical expertise, globally recognized certifications, and responsive service.

If you are seeking a reliable partner for automotive plastic injection molding design, development, or mass production, our technical team is ready to support you—from concept optimization to large-scale manufacturing.

Let’s work together to shape the future of lightweight and intelligent vehicles.