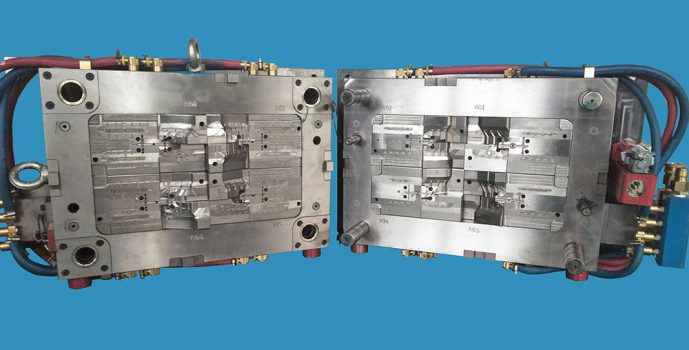

Automotive Plastic Components Mold Manufacturer

Precision Injection Molds for Interior & Functional Automotive Parts

- OEM / ODM Custom Mold Development

- High Precision & Long Mold Life

- Automotive Industry Standards Compliance

Get a Quote

Automotive Plastic Components Mold

Idealmold specializes in automotive plastic components mold manufacturing, providing reliable injection mold solutions for OEM and Tier suppliers.

Our molds are widely applied in automotive interior, exterior, and functional plastic components with strict quality requirements.

Get a Quote

Recommended Products

-

Air Outlet Components

Read more -

Car Accelerator Pedal

Read more -

Gear Housing

Read more -

Automative Air Conditioner Outlet Decorative Ring

Read more -

Automative Dashboard

Read more -

Automative Outlet Components

Read more -

Connector

Read more -

Connector

Read more -

Automobile Oil Filter

Read more -

Automobile Oil Filter

Read more

Why Choose Idealmold

Precision Mold & Injection Molding Partner Since 2005

20+ Years Experience

Over two decades of expertise in precision injection molds and automotive parts.

20,000㎡ Manufacturing Base

Large-scale modern factory ensuring stable production and on-time delivery.

Advanced Equipment

Makino, Fanuc, Sodick CNC & EDM machines for high-precision tooling.

Strong Production Capacity

47 injection machines from 60–1000 tons, supporting multi-cavity molds.

Professional Engineering Team

30+ skilled engineers covering mold design, manufacturing, and molding.

Global Trusted Partner

Serving Tier-1 customers like VOLVO, GM, Ford, LG, and Corning.

Factory & Production Facilities

Credentials

Start Your Automotive Mold Project with Idealmold

Contact us today to discuss your custom automotive mold requirements.

Request a Quote

FAQ

How does Ideal ensure the quality and reliability of its products?

At Ideal, quality is a top priority. The company implements rigorous quality control processes throughout every stage of the manufacturing process, including design, material selection, production, and testing.

Using state-of-the-art technology and advanced manufacturing techniques, Ideal guarantees that each mold and product meets industry standards and customer specifications. Regular inspections, including dimensional and performance testing, ensure that the final products are reliable and high-quality.

What is the typical lead time for custom mold production at Ideal?

The lead time for custom mold production at Ideal varies depending on the complexity of the design and the type of molding required. On average, estimates a lead time of 4 to 6 weeks for most standard projects. For more complex molds, the timeline may be longer, but Ideal works closely with clients to establish clear expectations and ensure timely delivery. The company prioritizes efficiency without compromising on quality to meet customer deadlines.

What is the process for starting a custom mold project with Ideal?

Clients can begin by contacting our sales or project management team to discuss needs. Ideal will then conduct an initial consultation to understand the project’s requirements, including product specifications, material choices, and production volume. Afterward, the design phase begins, where the team develops 3D models and prototypes for client approval. Once the design is finalized, Ideal proceeds with mold fabrication, testing, and production. Throughout the process, clients are kept informed, ensuring a collaborative and transparent experience.

Can Ideal handle large-scale production runs for businesses?

Yes, Ideal is equipped to handle large-scale production runs. Our company’s advanced injection molding facilities, combined with our experience in managing high-volume production, allow our to efficiently scale production to meet large orders. We offers flexible solutions to accommodate various production volumes, whether it’s a small batch or large-scale manufacturing, ensuring consistent quality and cost-efficiency throughout the process.