In today’s competitive automotive industry, precision and efficiency define success. Among all manufacturing methods, automotive plastic injection molding stands out as one of the most reliable and cost-effective ways to produce high-quality car components. From dashboards to bumpers, from small clips to complex light housings, injection molding makes it possible to deliver consistent parts at scale.

At Ideal, we are proud to be a professional automotive plastic mold manufacturer. With years of experience, advanced technology, and a customer-focused approach, Ideal has established itself as a trusted automotive mold supplier for global car brands and OEMs.

1. What is Automotive Plastic Injection Molding?

Automotive plastic injection molding is a process where melted plastic is injected into a mold cavity under high pressure. Once cooled, the plastic solidifies into durable, precise components.

This technique is ideal for the automotive sector because it enables manufacturers to:

- Produce complex designs that are difficult with other methods.

- Achieve consistency and accuracy, essential for safety-critical parts.

- Reduce costs in mass production.

By working with a reliable China automotive mold factory like Ideal, customers can ensure high efficiency and world-class quality.

2. Applications of Automotive Plastic Injection Molding

Plastic injection molding is used in nearly every area of modern vehicles. Common applications include:

- Interior components: dashboards, air vents, center consoles, door panels, and trim parts.

- Exterior components: bumpers, grilles, mirror housings, and light housings.

- Functional components: clips, connectors, fasteners, and under-the-hood parts.

Ideal specializes in delivering custom automotive molds for both interior and exterior applications, ensuring that every detail matches our clients’ performance and aesthetic requirements.

3. Why the Automotive Industry Relies on Injection Molding

The demand for automotive plastic injection molding continues to grow due to:

- Lightweighting – Plastic helps reduce vehicle weight, improving fuel efficiency and supporting EV innovation.

- Design flexibility – Complex geometries can be achieved without compromising durability.

- Cost-effectiveness – Once tooling is complete, large production runs are highly economical.

- Reliability & quality – Injection-molded parts consistently meet strict industry standards.

For this reason, most global automakers rely on experienced automotive plastic mold manufacturers like Ideal.

4. Challenges in Automotive Plastic Injection Molding

Producing automotive components through injection molding requires overcoming several challenges:

- Precision and durability – Automotive parts must perform reliably for many years.

- Material performance – Parts must resist heat, vibration, and chemical exposure.

- Surface quality – Interior and exterior components require flawless finishes.

- Compliance and certification – International standards such as IATF 16949 and ISO 9001 are essential.

Ideal addresses these challenges by combining cutting-edge equipment with deep technical expertise, making us a reliable choice among China automotive mold factories.

5. Why Choose Ideal as Your Automotive Mold Supplier

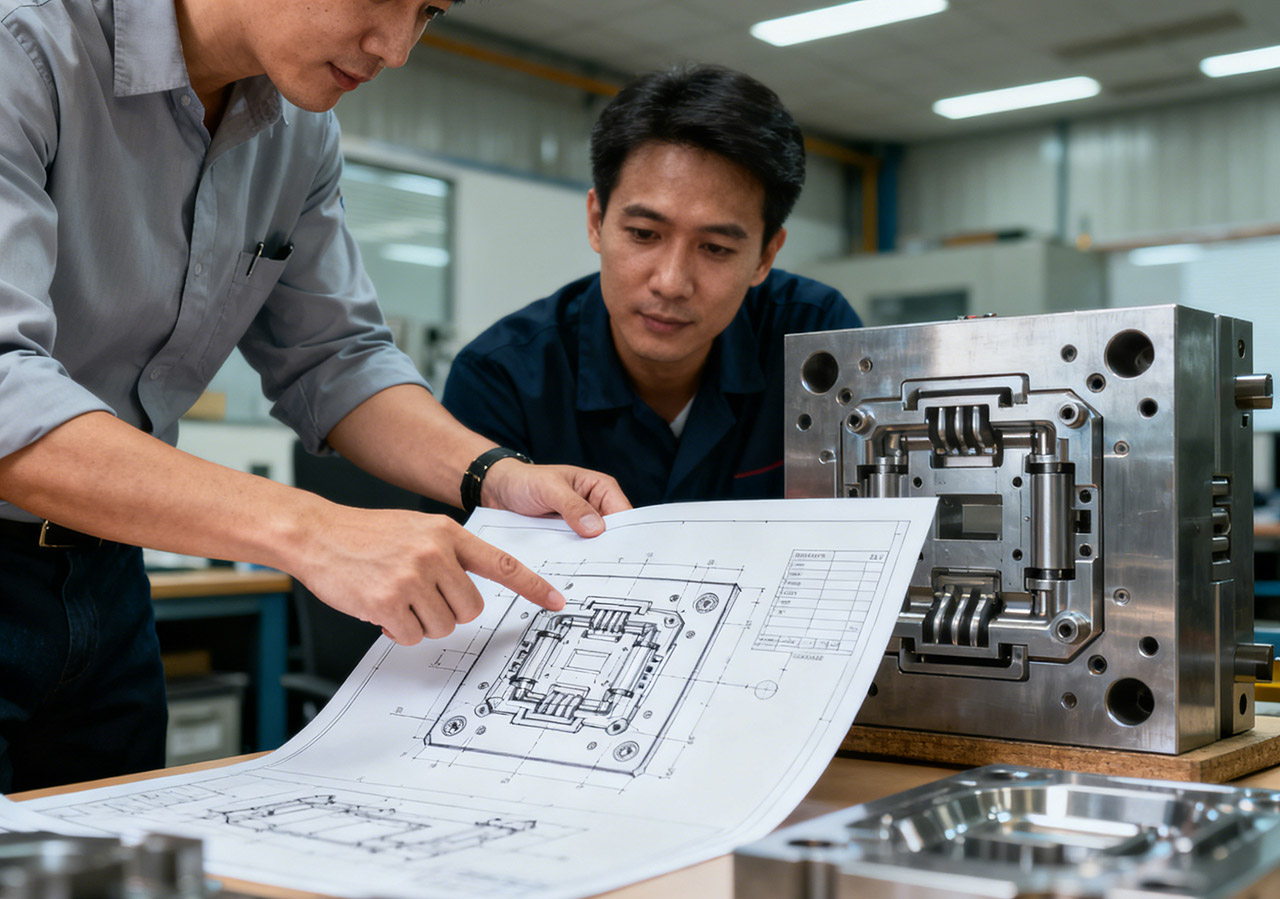

At Ideal, we believe that the mold is the foundation of every automotive component. Our strengths include:

- Advanced manufacturing facilities – Precision CNC, EDM, and high-performance tooling systems.

- Expert engineering team – Experienced mold designers who optimize for cost, strength, and performance.

- Strict quality control – Every mold passes through multiple stages of testing and validation.

- Custom solutions – We deliver custom automotive molds tailored to each client’s needs.

As a leading automotive plastic mold manufacturer, Ideal has built long-term relationships with automotive brands across Europe, North America, and Asia.

6. Case Study: Automotive Air Vent Mold

A recent project involved designing and manufacturing a custom automotive mold for an air vent system. The client required complex geometry, durability, and a high-gloss finish.

By leveraging our advanced tooling technology, Ideal delivered a mold that ensured precise airflow control and a premium appearance. This case highlights why global clients trust Ideal as their go-to automotive mold supplier.

7. Future Trends in Automotive Plastic Injection Molding

The future of the automotive industry is closely tied to injection molding technology. Key trends include:

- Electric vehicles – More lightweight plastic components to increase driving range.

- Sustainability – Wider use of recyclable and bio-based plastics.

- Automation & Industry 4.0 – Smart manufacturing for higher efficiency and consistency.

As a forward-thinking automotive plastic mold manufacturer, Ideal continues to invest in research and technology to meet these new demands.

8. Conclusion

Automotive plastic injection molding is at the heart of modern car manufacturing, enabling lightweight, durable, and cost-effective solutions for the automotive industry.

As a professional automotive mold supplier, Ideal provides high-quality, customized solutions that meet the strict demands of global automotive manufacturers. Whether you need interior, exterior, or functional components, Ideal delivers precision and reliability.

👉 If you are looking for a trusted China automotive mold factory that specializes in custom automotive molds, choose Ideal. Let us be your partner in shaping the future of mobility.