In modern manufacturing, injection molding has become one of the most efficient and widely used methods for producing plastic components. From automotive parts and electronic housings to medical device enclosures, this technology plays a vital role across countless industries.

But how exactly does a plastic product go from concept to finished part?

This article walks you through every key stage of the injection molding process—from mold design to final shipment—so you can better understand how precision and efficiency come together in this highly technical craft.

1. Planning and Mold Design – Building the Foundation of Quality

Every high-quality molded part begins with careful planning and precise design.

At the early stage, engineers create a 3D model based on the customer’s specifications and select the most suitable raw materials, such as ABS, PP, PC, or PA.

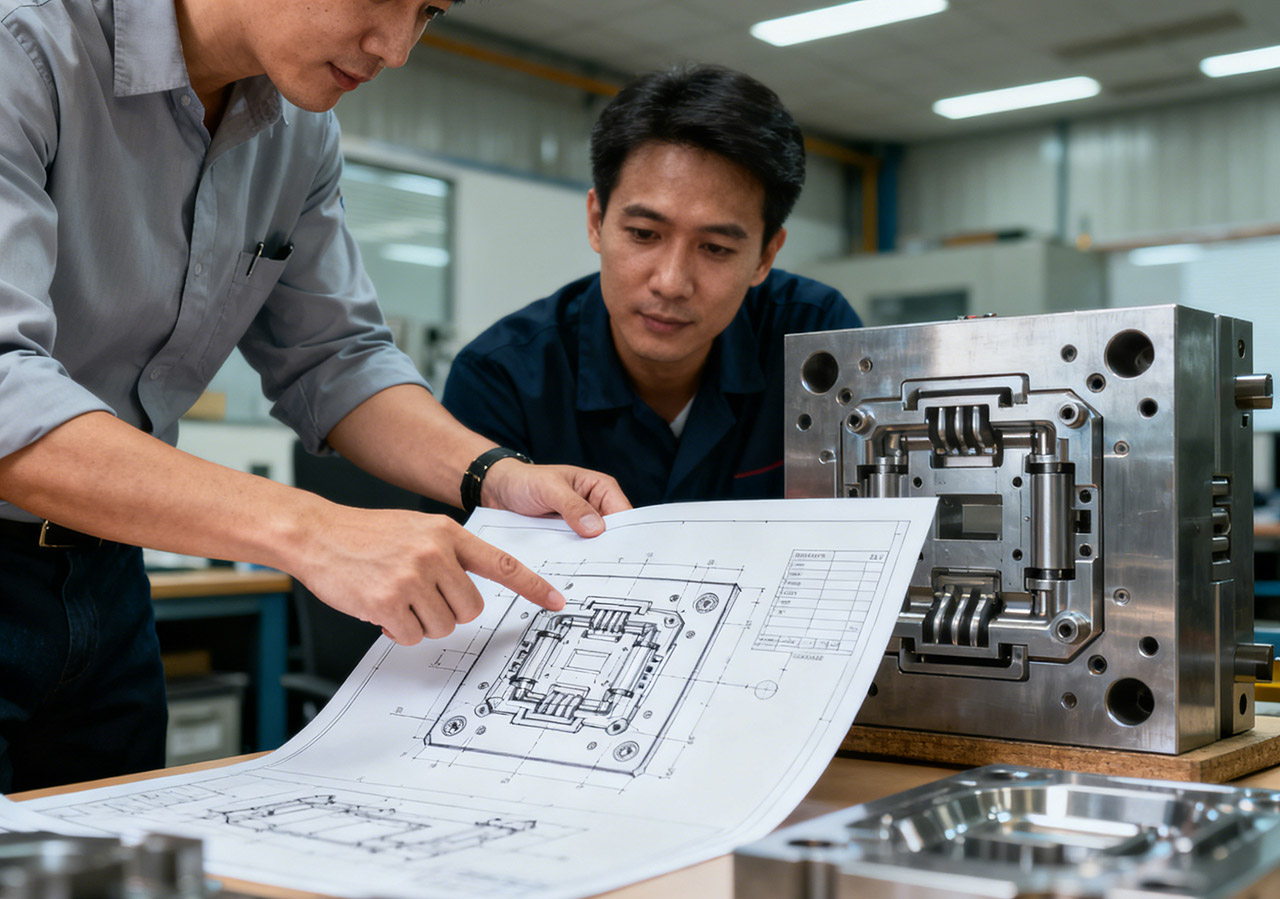

Next comes mold design, the true “heart” of the injection molding process. The mold’s precision and durability directly affect product performance and appearance.

Designers must consider multiple factors, including:

- Plastic flow behavior and shrinkage rate

- Cooling system layout

- Gate position and draft angles

These elements may seem minor but have a major impact on production stability and product quality.

Using Computer-Aided Design (CAD) and Computer-Aided Engineering (CAE) software, engineers can simulate the molding process, identify potential problems, and optimize the design before manufacturing even begins.

Tip: A high-quality mold may cost more initially, but it ensures higher consistency, lower maintenance costs, and smoother long-term production.

2. Material Preparation – Ensuring Consistent Performance

Once the mold is ready, the next step is material pretreatment.

Most thermoplastics are hygroscopic—they easily absorb moisture from the air. If not properly dried, this can cause bubbles, silver streaks, or weak spots in the finished part.

Therefore, the plastic pellets must be thoroughly dried before processing, typically reducing the moisture content to below 0.2%.

Color masterbatches or functional additives may also be mixed in to achieve the required appearance or performance.

Though simple in concept, this step is crucial. Proper material preparation ensures stable flow and uniform filling during molding, leading to flawless surface finish and reliable mechanical strength.

3. Injection Molding – The Core of the Process

This is the most critical and technically demanding part of production.

Molten plastic is injected into the mold cavity under high pressure using a screw-driven injection unit.

During this phase, temperature, pressure, and speed must be precisely controlled:

- Too much pressure may cause flash or overflow.

- Too little injection speed can result in incomplete filling.

- Improper temperature affects crystallization and material strength.

Modern injection machines are equipped with intelligent control systems that monitor these variables in real time and automatically adjust them for consistent results.

The packing and holding stage that follows helps compensate for material shrinkage, ensuring excellent dimensional accuracy.

4. Cooling and Demolding – Turning Melt into Form

After injection, the molten plastic must cool and solidify within the mold.

The cooling time directly impacts cycle efficiency and product stability. Cooling too fast may lead to internal stress or warping, while insufficient cooling affects shape precision.

Once the part has hardened, the mold opens automatically, and robotic arms remove the molded component.

At this stage, minor imperfections such as flash or burrs are trimmed away. Complex or high-precision parts may undergo secondary operations such as drilling, coating, or laser marking.

A well-designed ejection system ensures the part is released smoothly without damage.

5. Post-Processing and Quality Inspection – Pursuing Perfection

Freshly molded parts often require finishing and inspection before they can be shipped.

Typical post-processing tasks include:

- Deburring and polishing

- Surface coating or printing

- Assembly or functionality testing

Next comes quality control. Using precision instruments such as calipers, coordinate measuring machines (CMM), optical projectors, and even CT scanners, inspectors verify that dimensions and tolerances meet design specifications.

Functional tests, including tensile strength and weather resistance, ensure the parts can withstand real-world conditions.

Only products that pass every test are approved for packaging and delivery.

6. Packaging and Delivery – Ensuring Safe Arrival

Approved products are packaged according to the order quantity, with all required documentation—such as inspection reports and product labels—attached.

To prevent damage during transport, protective cushioning materials like foam or bubble wrap are used.

Timely and reliable logistics service is also a key indicator of a manufacturer’s overall capability.

Professional suppliers continue to follow up after delivery, gathering customer feedback to continuously refine their molds and production processes.

Conclusion: Precision Creates Quality

From initial design to final delivery, every stage of injection molding requires precision, expertise, and attention to detail.

It’s not just a manufacturing process—it’s a commitment to quality.

Through careful planning and process control, manufacturers can maximize material performance, reduce production costs, and deliver high-quality, cost-effective products.

Injection molding may seem complex, but it’s this very precision and consistency that make it one of the most trusted technologies in modern manufacturing.