As the automotive world rapidly shifts toward electrification, lightweighting, and intelligent design, the importance of precision injection molds has never been greater. These molds serve as the “mother tools” behind countless components—meaning their quality directly affects a vehicle’s safety, durability, and performance. For manufacturers seeking reliable long-term partners, choosing the right automotive injection mold supplier is no longer just a procurement decision—it’s a strategic move that can reduce risk and strengthen competitiveness.

This article explores what defines a truly exceptional automotive injection mold supplier in today’s demanding market.

1. Mastery of Technical Capabilities: Solving Real Automotive Challenges

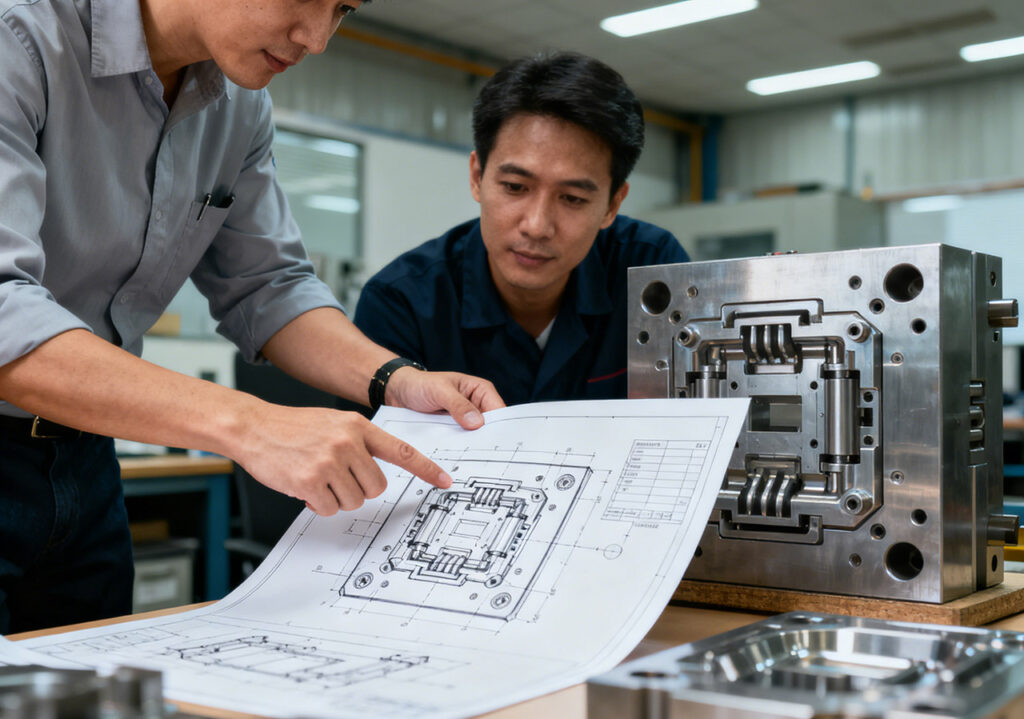

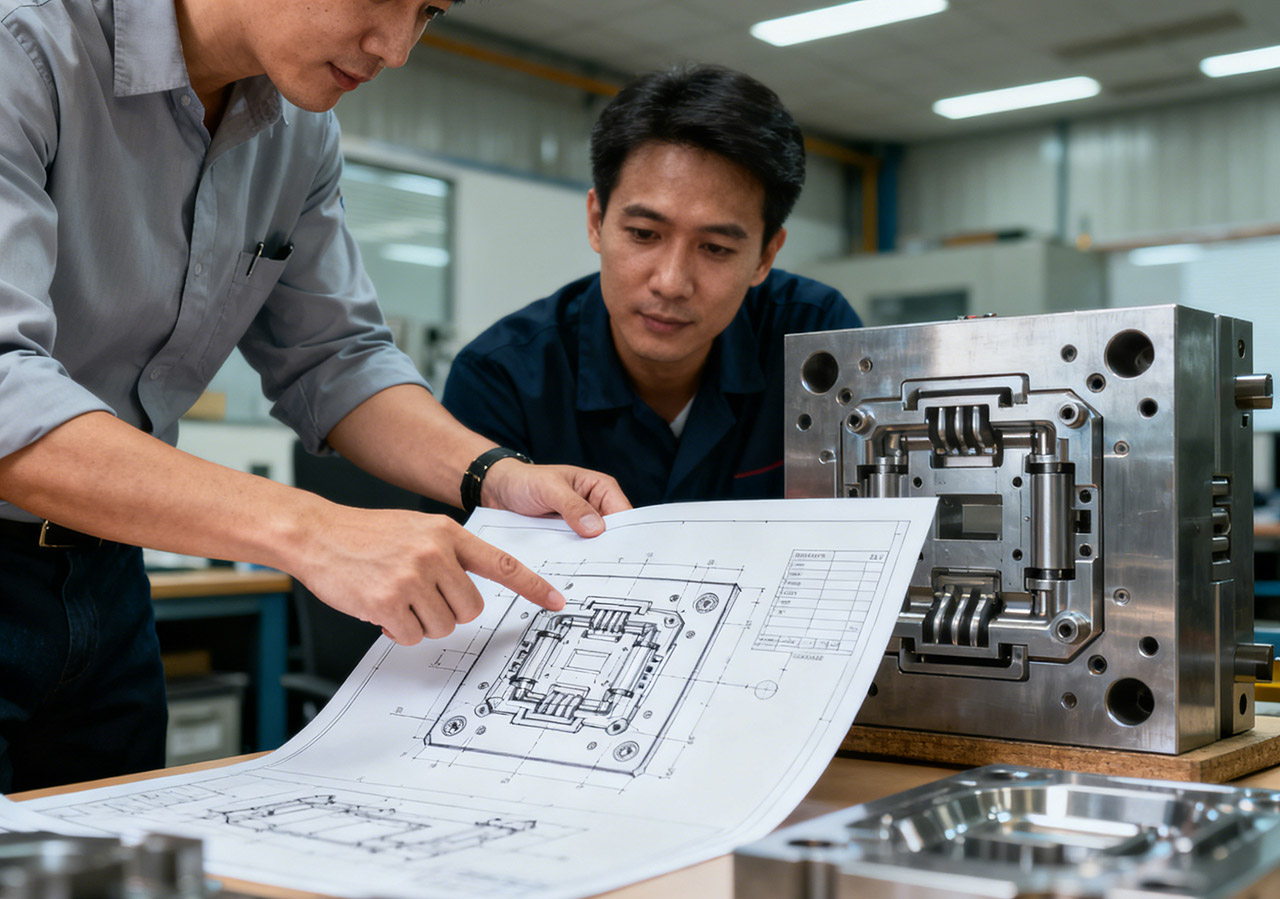

A top-tier automotive injection mold supplier does far more than upgrade generic molds. Automotive components require precise tolerances, material expertise, and process-driven engineering that only specialized suppliers can achieve.

Precision Engineering as the Foundation

Automotive components—especially those related to safety or structural performance—often require tolerance control within ±0.005 mm. A qualified supplier must excel in:

- Full CAD/CAM/CAE workflow

- 3D modeling and mold-flow simulation

- Early detection of defects such as warpage, weld lines, shrink marks

For example, EV battery housings often require optimized cooling-channel design to maintain dimensional stability under high-temperature molding.

Deep Understanding of Automotive-Grade Materials

Automotive environments vary significantly—from interior trims to high-heat engine-bay components. Skilled suppliers must understand materials such as:

- PP

- ABS

- PC/ABS

- PA66 + GF

- Flame-retardant or high-impact engineering plastics

They should also be able to recommend the best material–process combination to balance performance and cost.

Advanced Manufacturing Processes

Leading suppliers continuously upgrade their processes, including:

- Hot runner systems

- Two-shot and multi-shot molding

- Gas-assisted injection molding

- Complex parting-line optimization

These technologies improve appearance, stability, and mass-production efficiency—particularly for large structural components like dashboard frames.

2. Proven Industry Experience Across All Automotive Scenarios

Automotive manufacturing is extremely diverse, and experience matters. A trustworthy automotive injection mold supplier should demonstrate industry-focused case accumulation rather than general plastic-molding background.

A Wide Portfolio of Automotive Mold Projects

This includes molds for:

- Interior parts: dashboards, door panels, air vents

- Exterior parts: bumper systems, grilles, lamp housings

- Functional parts: gearbox housings, sensor covers

- EV-specific components: battery shells, motor covers, charging parts

Such coverage ensures the supplier can respond quickly to new component designs.

Familiarity With Global OEM Standards

A mature supplier typically understands the standards of brands such as:

- Toyota

- Volkswagen

- BMW

- BYD

- Tesla

They should also operate under ISO/TS 16949 or IATF 16949 systems, ensuring consistency from design to mass production.

Validation Under Real Production Conditions

A strong supplier must demonstrate mold durability and stability in high-volume production. For instance, molds capable of running over one million cycles while maintaining 99%+ part consistency illustrate true engineering robustness.

3. Industry Recognition: Building Authority and Trust

Authority is one of the strongest differentiators in choosing an automotive injection mold supplier.

Mandatory Certifications

Top suppliers typically hold:

- IATF 16949

- ISO 9001

- UL, RoHS and other material or component certifications

These guarantee that their processes align with global automotive standards.

Partnerships With Leading Automotive Brands

Collaborations with well-known automotive OEMs or Tier-1 suppliers serve as powerful proof of reliability and capability. Verified case studies and long-term partnerships provide reassurance for new clients.

4. Reliability and Transparency: The Foundation of Long-Term Partnerships

Automotive supply chains demand stability. A dependable automotive injection mold supplier is defined not only by technical ability but also by professionalism and ethical business practices.

Transparent Communication

From design to mold trials, top suppliers deliver:

- Dedicated project managers

- Real-time progress updates

- Honest reporting of engineering challenges

This prevents misalignment and reduces project risk.

Strict Quality Control

A robust supplier maintains:

- Full traceability of raw materials

- Careful machining using high-precision equipment

- Comprehensive inspection (CMM, projectors, hardness testers, etc.)

Every step is documented to ensure the final mold meets promised specifications.

Comprehensive After-Sales Support

This includes:

- On-site installation and debugging

- Process optimization suggestions

- Training for mold maintenance

- 24/7 technical support for urgent production issues

Such services help customers maintain stable, continuous production.

Compliance and Integrity

A professional supplier avoids unethical behaviors such as:

- Under-quoting and hidden fees

- Unauthorized material substitutions

- Leaking confidential technical documents

Integrity ensures a sustainable partnership.

Conclusion: Choosing the Right Automotive Injection Mold Supplier Matters

In today’s competitive environment, companies should look far beyond pricing when selecting an automotive injection mold supplier. The true value lies in the supplier’s engineering depth, industry experience, certifications, quality systems, and commitment to long-term service.

A reliable partner not only delivers high-precision, high-durability molds but also contributes to continuous product improvement and competitive advantage. When evaluating suppliers, be sure to review their production facilities, confirm certification validity, and assess real customer cases.

If you’re searching for an automotive injection mold supplier with strong technical capability and a proven track record, choosing one with comprehensive design-to-delivery service and robust industry certifications will ensure your project stays on track and ready for future challenges.