In the manufacturing of plastic products, injection molding is one of the most widely used processes. It not only enables large-scale production but also ensures high consistency in appearance, structure, and functionality. Beyond conventional injection molding, advances in product design and technology have led to the development of specialized processes that meet diverse demands for aesthetics, functionality, lightweight structures, and customization.

In this article, we will explore seven major injection molding processes: two-shot and multi-shot molding, overmolding, insert molding, nano molding, foam injection molding, paint-free molding, and injection compression molding. Whether you are a product designer, engineer, or manufacturing professional, understanding these processes will give you deeper insight into the technology behind plastic products.

1. Two-Shot and Multi-Shot Molding

Two-shot molding, also known as dual-material injection, is a mature and widely used technology. It allows two different materials to be molded into a single product, achieving diverse visual effects such as contrasting colors or different surface textures. This not only enhances design flexibility but also improves efficiency and reduces costs.

As market demands grow, two-shot molding has evolved into three-color or multi-shot molding. This technology enables the integration of multiple colors, soft-touch materials, embedded logos, and even electronic components directly into one product. The result is reduced assembly, lower production costs, and the ability to create compact, multifunctional, and personalized products.

Applications: consumer electronics, home appliances, automotive interiors, customized products.

2. Overmolding

Overmolding involves molding an additional layer of material over an already-molded plastic part. The first material is called the substrate, while the second material is the overmold. By combining these materials, manufacturers can add functionality such as a soft-touch surface, shock absorption, waterproofing, or enhanced durability.

This technology has been developed for more than 20 years and is especially common in the medical field, where products often require a soft, ergonomic surface. Overmolding is also widely used in consumer electronics and household goods to improve both appearance and performance.

Applications: medical devices, home appliances, consumer electronics, toys, sporting goods.

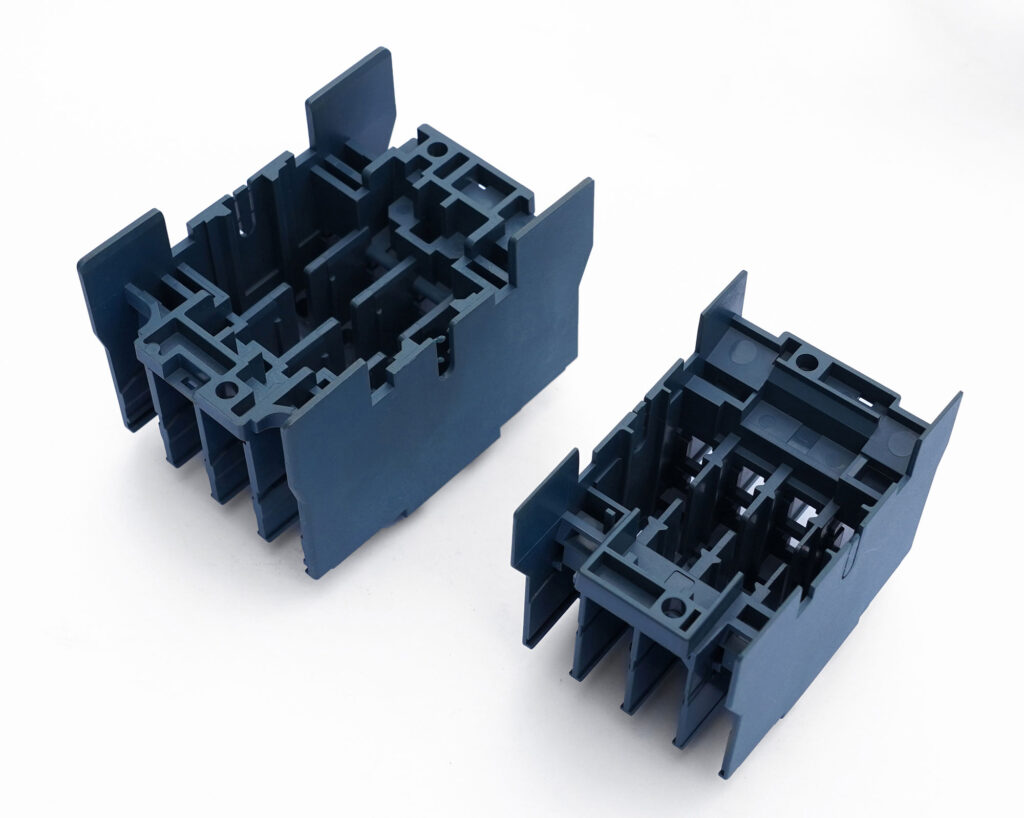

3. Insert Molding

Insert molding involves placing a pre-made insert (often metal or another material) into the mold, and then injecting plastic around it to form a single integrated product. For example, magnetic building blocks use insert molding to embed magnets into the plastic structure.

This process combines the strength of metal with the versatility of plastic, ensuring high reliability while reducing the need for additional assembly. It is also highly suitable for automation and mass production.

Applications: electronic products, automotive components, home appliances, toys.

4. Nano Molding (NMT)

Nano molding technology rose to prominence around 2015 with the popularity of full-metal smartphone bodies. The process involves treating the metal surface at the nanoscale and then directly molding plastic onto it, creating a seamless bond between metal and plastic.

The main advantages include preventing signal interference caused by all-metal designs, achieving sleek and seamless surfaces, and reducing costs compared to CNC machining. It also enables thinner, lighter, and more compact products with excellent structural strength.

Applications: smartphones, laptops, wearable devices, precision electronics.

5. Foam Injection Molding

Foam injection molding introduces a foaming agent into the material, forming a lightweight, porous structure. Microcellular foam molding, in particular, uses supercritical fluids (such as nitrogen or carbon dioxide) to create microscopic bubbles within the plastic, resulting in lighter products while maintaining strength and dimensional stability.

Compared to conventional injection molding, foam injection molding reduces material usage and weight while enhancing insulation, cushioning, and precision control.

Applications: automotive parts, electronic housings, lightweight industrial products.

6. Paint-Free Molding

Paint-free molding eliminates the need for spray-painting or post-processing. By using specially engineered plastic pellets with metallic, ceramic, or fabric-like effects, products can achieve rich surface appearances directly during injection.

This technology not only reduces environmental impact but also simplifies the production process. However, it places higher demands on material selection and mold design to ensure smooth flow, durability, and high-quality finishes.

Applications: home appliances, beauty packaging, automotive interiors, consumer electronics.

7. Injection Compression Molding

Injection compression molding combines traditional injection molding with compression techniques, making it ideal for thin-walled products that require high precision and surface quality.

This process gained attention in 2018 with the rise of glass-like smartphone covers, where transparent polycarbonate (PC) was molded using this technique. The resulting products are thin, stable, and visually refined, with processes including injection, compression, CNC finishing, hardening, and polishing.

Applications: smartphone covers, high-end electronics, precision components.

Conclusion

With continuous industrial advancements and evolving consumer needs, injection molding has moved beyond simple plastic forming to embrace multifunctionality, lightweight design, personalization, and sustainability.

From the vibrant aesthetics of two-shot molding to the seamless integration of nano molding, and from the eco-friendly benefits of paint-free molding to the precision of injection compression molding, these technologies are shaping the future of product design and manufacturing.

For designers and manufacturers, understanding these processes is key to creating innovative products and staying competitive in today’s global market.