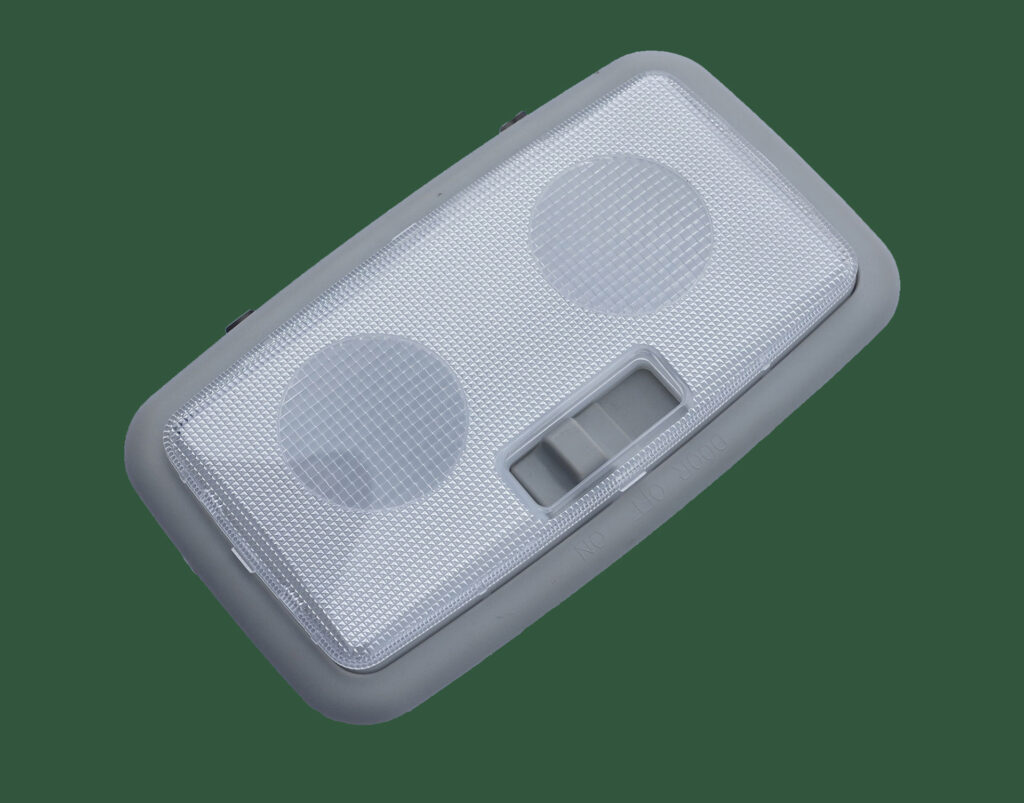

When it comes to automotive components, injection molding plays a central role in shaping the modern car. From bumpers and dashboards to trim panels and instrument housings, injection-molded parts make up a large portion of a vehicle’s total assembly.

This article provides a practical overview of how injection molding works in the automotive industry — including mold structure, classifications, working principles, and common molding defects — to help you better understand one of the most essential manufacturing technologies behind today’s vehicles.

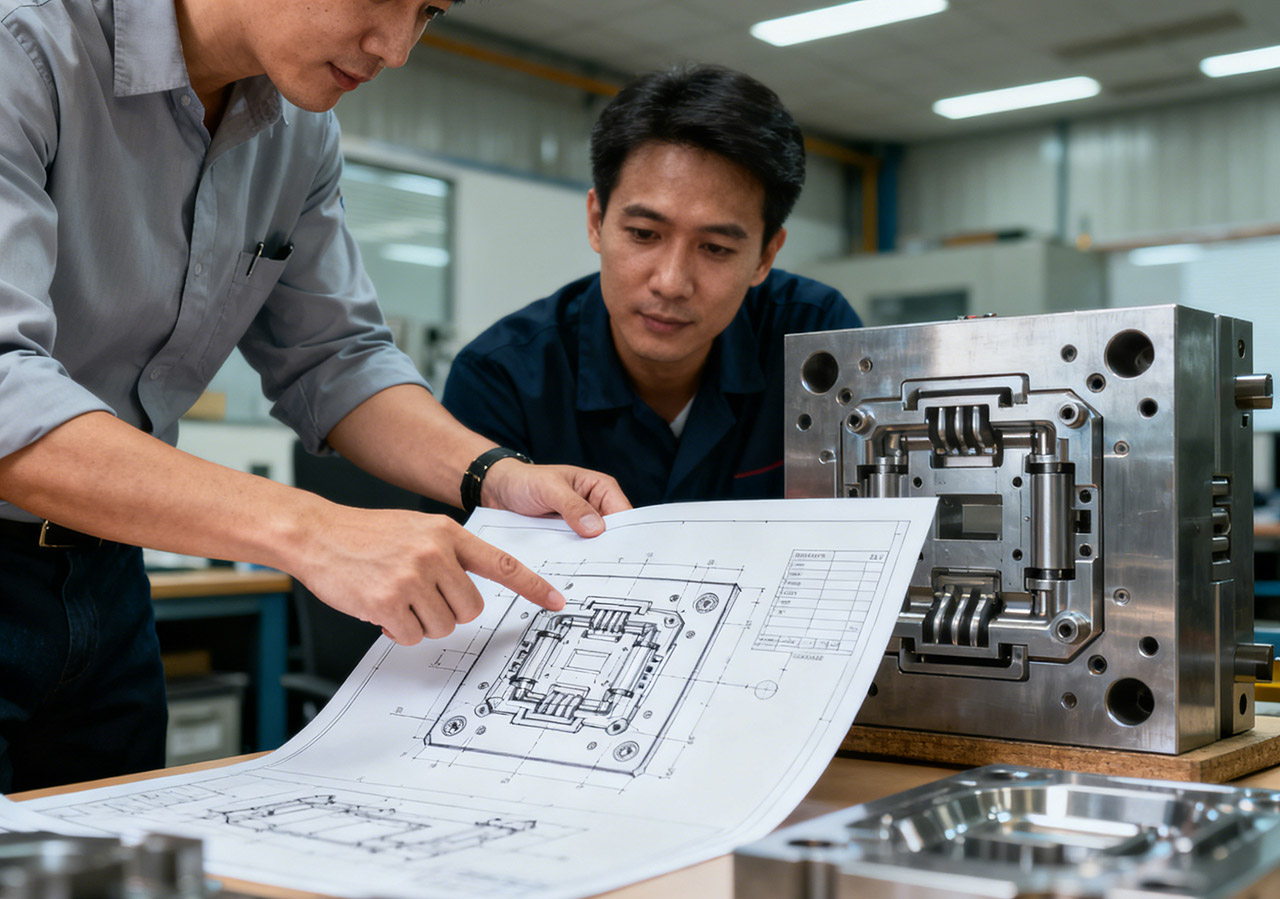

1. Structure of Injection Molds for Automotive Components

Injection molds are the core tools in the production of plastic automotive components. Their structure determines not only the shape and precision of each part, but also the overall quality and consistency of production.

A standard mold is composed of the following key systems:

(1) Forming System

The forming system defines the actual shape of the molded part. It includes the core (male mold), which forms the inner surface, and the cavity (female mold), which forms the outer surface of the plastic component.

(2) Gating System

This system channels the molten plastic from the injection machine into the cavity. It includes elements such as the sprue, runner, gate, and cold slug well. Proper gating design is essential for uniform filling and minimizing defects.

(3) Guiding System

To ensure precise alignment between the moving and fixed halves of the mold, guide pins and bushings are used. Without accurate guidance, parts can suffer from dimensional inaccuracy or surface defects.

(4) Side Core Pulling Mechanism

For automotive components with lateral holes, undercuts, or side bosses, this mechanism allows for side-parting and core-pulling during ejection. The most common method is the inclined guide pin (angle pin) and slider design.

(5) Ejection System

Once molding is complete, ejector pins push the cooled part out of the mold cavity. The system typically includes ejector plates, pins, and return springs to ensure smooth and damage-free removal.

(6) Cooling and Heating System

Temperature control is crucial. Cooling channels circulate water or oil to maintain optimal mold temperatures, while heating rods may be used when processing engineering plastics that require higher mold temperatures. Proper thermal control ensures consistent quality and shortens cycle time.

2. Classification of Injection Molds for Automotive Components

Depending on their structure and function, injection molds can be categorized into several types — each suited for different kinds of automotive parts.

(1) Single-Parting Surface Mold

This is the simplest and most common mold type. It consists of two halves — the fixed mold and the moving mold.

- Process: During molding, the two halves close to form the cavity. After injection and cooling, the mold opens, the runner is pulled, and the ejection system pushes out the part.

- Features: Simple, cost-effective, and suitable for a wide variety of automotive plastic parts.

(2) Double-Parting Surface Mold

In addition to the fixed and moving halves, this type adds a middle (runner) plate.

- Process: During the first parting, the runner and sprue are pulled out. The second parting then separates the molded part for ejection.

- Features: Allows for pin-point gating, which improves the appearance and reduces manual trimming — ideal for high-precision automotive interior components.

(3) Slanted Guide Pin (Angle Pin) Side Core-Pulling Mold

For complex automotive components with side holes or undercuts, this mold type uses the angle pin to drive sliders laterally as the mold opens.

- Features: Efficient side-core removal, suitable for intricate part geometries such as air vents or light housings.

(4) Molds with Movable Inserts

When side cores are not economical, movable inserts are used instead. Inserts are manually removed along with the molded part and replaced before the next cycle.

- Features: Simpler design and lower tooling cost, suitable for small-batch or prototype automotive components.

(5) Other Specialized Molds

Including gear-and-rack core-pulling molds, hot-runner molds, and multi-component molds, designed for specific part requirements and higher production efficiency.

3. Importance of Each Mold System in Production

Every part of an injection mold directly influences the outcome of the molded automotive component:

- The forming system dictates part accuracy and geometry.

- The gating system determines material flow, affecting internal strength and surface finish.

- The guiding system ensures precision during mold closing and opening.

- The core-pulling and ejection systems enable complex geometries and reliable demolding.

- The temperature control system governs shrinkage, cooling time, and part quality.

By optimizing each subsystem, manufacturers can enhance both productivity and part performance — two key factors in the competitive automotive supply chain.

4. Common Defects in Automotive Injection-Molded Components

In automotive manufacturing, especially for interior and exterior trim, visual and dimensional perfection is critical. Common defects include:

- Whitening or streaks on the surface

- Tiger stripes and flow marks

- Sink marks or flashes

- Ejector and insert marks

- Weld lines, warping, or color differences

- Uneven textures, cold slugs, and dimensional deviations

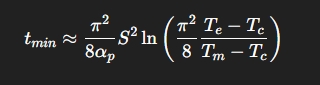

(1) Theoretical Minimum Cooling Time

The cooling time can be estimated using:

where:

- S = maximum wall thickness of the part

- αₚ = thermal diffusivity of the plastic melt

- Tₘ = melt temperature

- Tₑ = ejection temperature

- T꜀ = coolant temperature

Shorter cooling times lead to higher production efficiency, provided part quality remains stable.

(2) Methods to Shorten the Molding Cycle

To increase efficiency, automotive manufacturers use advanced systems such as hot runners, optimized gate designs, and high-speed injection machines.

For example:

- Redesigning the runner and using longer heated nozzles reduced one bumper cycle from 95s to 63s.

- Modern equipment like UBE-4000 presses can cut large-part cycles from over 120s to under 60s.

- Thinner-wall bumpers (2mm) in new models can reduce cycle time to around 40s.

These improvements directly enhance production throughput and lower costs for large-scale automotive component manufacturing.

5. Conclusion

Injection molding remains one of the most critical technologies in modern automotive manufacturing. From dashboard panels to complex under-the-hood components, the precision and efficiency of molds define the performance, safety, and aesthetics of the final vehicle.

Understanding the structure, types, and common challenges of injection molding helps not only engineers but also suppliers and project managers grasp how automotive components are brought from design to reality.

In the evolving landscape of lightweight materials, high-speed production, and sustainable manufacturing, mastering these fundamentals of injection molding is key to driving the next generation of automotive components.